1200℃ Long Keter Ceramic Fiber Blanket

Cooperation Years:4 Years

Product Sizes:25x7220x10320mm

Professional engineers guide you to screen high-temperature material for free.

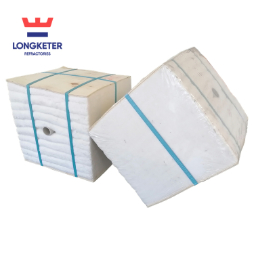

Long Keter ceramic fiber module is made of ceramic fiber blankets,After folded and fixed, the product looks like a cube. This ceramic fiber module can meet temperature requirements among 1100℃-1500℃ (2012-2732℉). In most parts of high temperature kilns, this module can be installed fast and easily, which improves the efficiency greatly. More importantly, the integral ceramic fiber insulation module is installed on the kiln by self-locking nuts and bolts. During subsequent replacement or repair, the modules do not affect each other. Ceramic fiber module has advantages of good chemical corrosion and long service life.

Get Long Keter Ceramic Fiber Module Price

Get Long Keter Ceramic Fiber Module Price

Long Keter ceramic fiber modules are designed for a non-anchored installation method, which contributes to their aesthetically pleasing appearance. At the same time, they provide a smooth and uniform surface, enhancing the visual appeal of kiln linings or other insulated areas. The clean and attractive appearance adds a professional touch to industrial settings.

Long Keter ceramic fiber modules are designed for a non-anchored There is a wide range of ceramic fiber module options to cater to diverse application needs. So customers can select modules with different dimensions, densities, and thicknesses to achieve the desired insulation performance. Meanwhile, this versatility of ceramic insulation products ensures that Long Keter ceramic fiber modules can be tailored to specific requirements, providing optimal thermal protection.

Compared to traditional insulation materials, LongKeter ceramic fiber module has the advantages of simple installation and reducing the load on kiln structures. Thus, their manageable weight makes them easier to handle during the installation process, improving efficiency and reducing labor requirements.

Long Keter ceramic fiber modules exhibit excellent stability in high-temperature environments. They maintain their structural integrity even under rapid temperature fluctuations, ensuring long-lasting insulation performance. So the modules’ stability minimizes the risk of cracking or damage, enhancing their durability and reliability.

Get Ceramic Fiber Module Price

The high-temperature industrial furnace industry is crucial for petrochemical enterprises, which are one of the pillar industries of our country's economy. Petrochemicals have played a significant role in the development of the national economy, and in recent years, energy conservation and emission reduction have become key objectives for this industry.

The furnace temperature of refinery heating furnaces is approximately 750-850℃, pure radiation furnaces are above 900℃, hydrogen production unit conversion furnaces are 1040-1050℃, and ethylene cracking furnaces are approximately 1150-1250℃.

Ceramic fiber modules are used as working layer of the furnace hearth, back layer for thermal insulation etc., help to save energy and improve the equiment working efficiency.

Our ceramic fiber module can help precisely control the firing curves, leading to the successful production of ceramics and glass. Our thermal management products have a low heat storage capacity, which allows furnaces to save energy and respond to load changes more easily. The better temperature uniformity in our products produces superior product quality. Long Keter ceramic fiber module also provides high-efficiency energy-saving program designs for ceramic glass industry to reduce energy consumption and ensure precise firing control.

Get Long Keter Ceramic Fiber Module Price

At Long Keter, we have a comprehensive quality control system in place for each production process. We also conduct tests on all goods post-production and include a quality certificate with each shipment.

We are truly a manufacturer, we not only can provide the high quality products with the best price, but also can offer the best pre-sale service and after-service.

Yes, free samples are available.

It usually needs about 15- 20 days after receiving the PO.

Yes, you are welcome to visit Long Keter and check our products.Also, we can talk more about the technique details.

We offer a minimum of 1 year warranty on our products. In case of any quality issues,we will take responsibility.

No limit, we can offer the best suggestions and solutions according to your condition.

We had been in this industry for more than 15 years, we are partners with Vesuvius for more than 5 years. We can not only provide you high quality products with competitive price, but also we can supply good technique service which can help you solve problems.

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.Third party testing is also accepted.

Get Price