In high-temperature sealing, insulation gaskets, and the fabrication of complex shaped components, the cutability, die-cutting precision, and bending stability of ceramic fiber paper directly determine processing efficiency and finished-part quality. However, many users encounter the following issues during actual operation:

Fiber pulling, fraying, or edge fuzzing during cutting

Cracking or delamination when bending

Structural instability when making complex shapes

The root cause of these problems is rarely operator skill; it lies in the material’s purity, fiber structure, and forming process.

LongKeter addresses these challenges through systematic process optimization, enabling easy cutting, precise die-cutting, and stable bending, especially for intricate high-temperature components.

Below is an analysis of why Long Keter ceramic fiber paper is easier to cut, from both material and process perspectives.

Uniform Wet-Formed Structure — The Core Factor Behind “Easy to Cut”

Long Keter ceramic fiber paper uses high-purity fiber cotton with impurity content below 1%, combined with an optimized wet-forming process. Fibers are fully dispersed in water and deposited uniformly, forming a continuous, dense, non-delaminated matrix structure.

Direct advantages include:

Clean cutting edges with no fiber pulling or debris

Continuous fibers that prevent cracking during bending

A stable base for producing complex shaped parts

Only with uniform fiber distribution can ceramic fiber paper reliably serve as a substrate for precision-shaped components.

Intelligent Deep Drying — Maintains Flexibility and Prevents Edge Cracking

Long Keter ceramic fiber paper employs an intelligent drying system that ensures synchronized drying from the inside out, avoiding the “dry outside, wet inside” problem common in conventional processes, which causes internal stress concentration.

Processing performance is significantly improved:

Bend without cracking; die-cutting without delamination

Firm, compact cutting edges

Greatly enhanced overall flexibility and tensile strength

High-Precision Cutting — Accurate Forming of Complex Geometries

Long Keter utilizes high-precision CNC cutting equipment and automated die-cutting platforms. Servo control and visual-positioning systems enable highly consistent precision cutting.

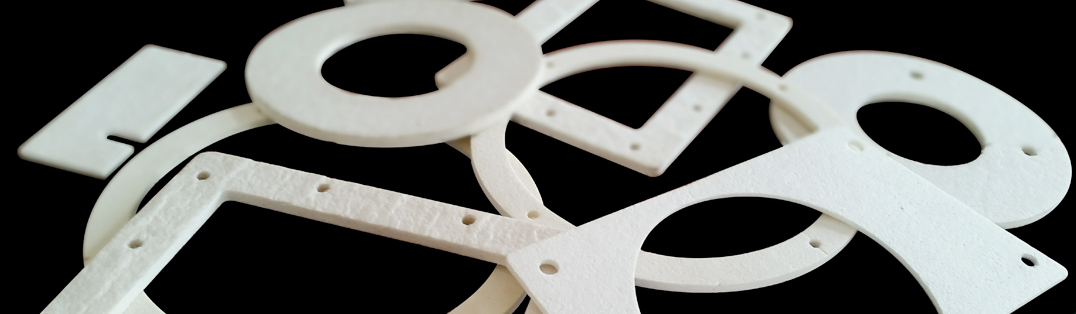

Capable of processing complex shapes such as:

U-shaped and L-shaped components

Ring gaskets and ultra-thin 0.5 mm pads

Wave forms, slots, perforated shapes, and custom geometries

Intelligent Quality Inspection — Ensuring Every Roll Cuts the Same

Long Keter integrates its independently developed Fiber Micro-defect Detection System Based on Image Recognition Technology V1.0, which continuously monitors surface flatness, fiber distribution, and thickness uniformity. The system automatically adjusts process parameters based on real-time data.

This ensures every roll has:

Consistent cutability and bending performance

Stable forming characteristics

Reliable, uniform quality

High-Purity Materials + Advanced Processing = Superior Cutability and Formability

Whether ceramic fiber paper is easy to cut and shape fundamentally depends on:

Raw material purity

Uniformity of the wet-forming process

Drying quality

Precision cutting equipment

Quality-control systems

Through fully integrated process control, LongKeter ceramic fiber paper delivers excellent cutability, die-cutting precision, and bending stability, making it highly suitable for the production of complex high-temperature seals and customized thermal-insulation shapes.

Long Keter Ceramic Fiber Paper That Is Truly “Easy to Cut, Easy to Shape, and Easy to Form.”